Everything You Need to Know About the China Final Inspection

As global trade continues to flourish, China has cemented its position as one of the world’s leading manufacturing hubs. The country’s cost-effectiveness, extensive infrastructure, and skilled workforce have attracted businesses worldwide seeking to source products at competitive rates. However, with the distance and potential communication barriers, ensuring the quality and compliance of goods manufactured in China is crucial. This is where the China Final Inspection plays a pivotal role in the supply chain process. In this article, we will explore everything you need to know about this critical step in the import process.

What is China Final Inspection?

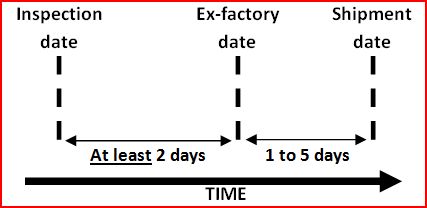

The China Final Inspection, also known as Pre-Shipment Inspection (PSI) or Final Random Inspection (FRI), is a quality control measure undertaken by international buyers or their representatives to assess the quality, quantity, and conformity of goods before they are shipped from China. The inspection occurs at the end of the production process when 80-100% of the order is completed, and the goods are ready for shipment.

Purpose of China Final Inspection

The primary purpose of the China Final Inspection is to minimize risks associated with importing goods from China. It ensures that the products meet the buyer’s specifications, adhere to regulatory standards, and are free from defects or damages. By conducting the inspection before shipment, buyers can identify and rectify any issues, reducing the chances of receiving substandard products and preventing costly returns or recalls.

Key Components of China Final Inspection

- Visual Inspection: The inspector examines the appearance and overall quality of the goods. They check for defects, damages, color discrepancies, labeling accuracy, and proper packaging.

- Quantity Check: The inspector verifies that the correct quantity of goods is ready for shipment, preventing shortages or excess inventory.

- Workmanship Assessment: This involves evaluating the workmanship and craftsmanship of the products to ensure they meet the buyer’s quality standards.

- Functionality Testing: If applicable, the inspector tests the functionality and performance of the products to ensure they operate as intended.

- Safety and Compliance Checks: The inspector ensures that the products comply with relevant safety regulations, certifications, and industry standards.

- Packaging and Marking: The packaging is assessed to confirm that it provides sufficient protection during transit, and the labeling is accurate and informative.

- On-site Testing: In some cases, the inspector may conduct on-site tests or collect samples for laboratory testing to verify specific product characteristics or compliance.

Selecting an Inspection Agency

Choosing a reputable and experienced inspection agency is crucial for a successful China Final Inspection. The agency should have a deep understanding of the industry, relevant product knowledge, and a track record of conducting reliable inspections. Many businesses collaborate with third-party inspection companies, which are independent entities not associated with either the buyer or the manufacturer, ensuring impartiality and objectivity.

Benefits of China Final Inspection

- Quality Assurance: The inspection guarantees that the goods meet the buyer’s quality standards, reducing the risk of receiving faulty or defective products.

- Cost Savings: Identifying issues before shipment helps avoid costly returns, recalls, and rework expenses.

- Timely Delivery: By catching any discrepancies early on, delays can be minimized, and products can be shipped promptly.

- Compliance and Safety: The inspection ensures that products meet regulatory and safety standards, preventing potential legal issues or customer complaints.

- Supplier Accountability: Regular inspections encourage suppliers to maintain consistent product quality and take responsibility for their manufacturing processes.

Conclusion

The China Final Inspection is an essential step in the import process, providing buyers with confidence in the quality and conformity of goods sourced from China. By ensuring that products meet the desired standards and regulatory requirements, businesses can mitigate risks, enhance customer satisfaction, and maintain a competitive edge in the global market. Collaborating with reputable inspection agencies and conducting regular inspections can significantly contribute to the success of international trade endeavors and fruitful business relationships between buyers and Chinese manufacturers.